What to Look for When Buying a Quiet Gas Furnace.

Have you ever sat in your comfy chair to watch a favorite TV show only to have to turn up the volume because the furnace kicked on? You wonder, “Why is my furnace so loud?” Well, you’re not alone – many homeowners have asked the same

question.

This post will describe the features that make some gas furnaces quieter than others and provide you with the knowledge needed when shopping for that quiet furnace!

There are two main design features to look for when shopping for a quiet furnace. They are:

1. Two or More Stages of Heat Output

There are two types of gas furnaces that have two or more stages of heat output: two-stage combustion and

modulating combustion. Here’s a short summary on the differences and benefits of each.

a. Two-Stage

Combustion

The majority of gas furnaces in operation today are single-stage designs with a single level of heat output.

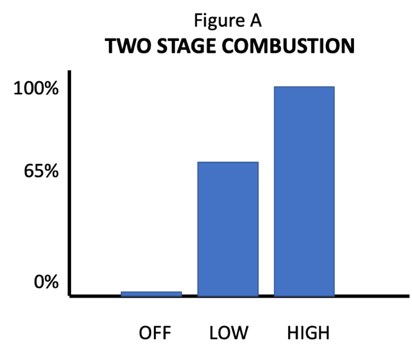

They are either ON at full heat output or OFF. Two-stage designs, however, have an intermediate level of heat output (typically ~ 65% of high heat stage). They are automatically controlled by the house thermostat to be either ON at high heat, ON at low heat, or OFF. This is depicted in Figure A below where the furnace can operate at low heat (65% of full capacity) and high heat (100% of full capacity).

The sound benefit comes from operating at the low heat stage, where the circulating and combustion blowers operate at a lower speed, and combustion intensity is greatly reduced.

In many applications, a two-stage gas furnace will operate most of the heating season on low stage to maintain indoor temperature (1), thus providing the sound benefit nearly all winter long. The high heat stage is then available to maintain temperature, or rapidly heat up the house, when low heat stage is not sufficient.

b. Modulating

Combustion

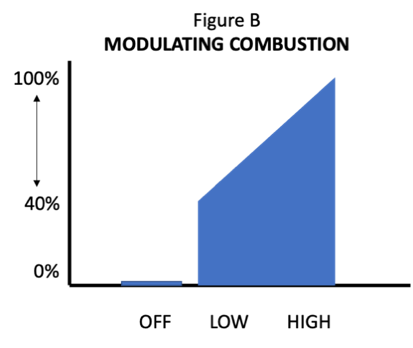

Modulating combustion takes the benefits of two-stage even further. The low heat stage usually has less

heat output than a two-stage design, typically 40% of high stage vs. 65% for two-stage. This means the circulating and combustion blowers can operate at even lower speeds, with a corresponding reduction in combustion intensity.

Unlike a two-stage furnace, which operates on either low OR high stage (and nowhere in between), a modulating furnace will gradually increment heat stage up and down, once it’s cold enough to operate constantly on low stage. This is depicted by the gradual sloped ramp between low and high stage in Figure B.

Often times in winter, a modulating furnace will run for the whole day without shutting down. It operates constantly and gradually adjusts heat stage to provide precise thermostatic temperature control; providing draft-free warmth and comfort.

The sound benefit of operating at the very low blower speeds and combustion intensity is significant. As shown later in this post, a modulating furnace operating on the lowest heat stage is significantly quieter than when operating on the highest heat stage.

Continuous operation without cycling ON and OFF provides sound benefit as the increment in heat output and airflow is gradual, and not as noticeable as furnaces that cycle ON and OFF to maintain temperature.

Lastly, the continuous and gradual increment in heat output also provides very precise temperature control. Read more about this in my prior post, “What is a Thermostat and How does it Affect Comfort?” .

2. Sealed

Combustion

Many modern gas furnaces, primarily those with an AFUE rating of 90% or higher, can

Many modern gas furnaces, primarily those with an AFUE rating of 90% or higher, can

be installed as open combustion or sealed combustion. (2) Open

combustion is when air is taken from the area surrounding the furnace to

combust the gaseous fuel. Sealed combustion designs, however, have an

enclosed chamber (“sealed”) and air for combustion comes from outside the house

through a plastic pipe. The sealed chamber traps the combustion sound

from escaping, thus reducing overall sound level as compared to open

combustion.

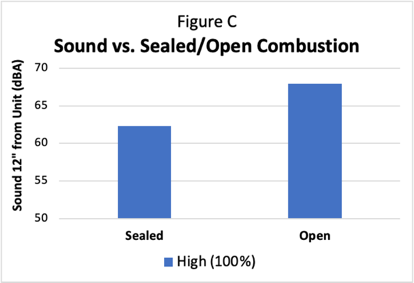

This is shown in Figure C, where the test results for my furnace show a 5-dBA sound benefit with sealed

combustion on high fire. (3) Sealed combustion also provides a slight energy benefit, irrespective of the AFUE rating, as heated air inside the house is not used.

There are code requirements, however, regarding the installation and location of the combustion air intake

outside the house. The combustion air intake can be susceptible to frost and ice buildup, particularly in extreme cold. It can also become blocked by snow drifts, if located too close to the ground. Be sure to consult with your HVAC contractor on whether a sealed combustion system would be appropriate for your house. (4)

To quantify the sound benefit of two-stage, modulating and sealed combustion, I ran experiments on the furnace in my own home. It is a sealed combustion, modulating design that increments heat output in 1% steps, from 40% to 100% of rated capacity.

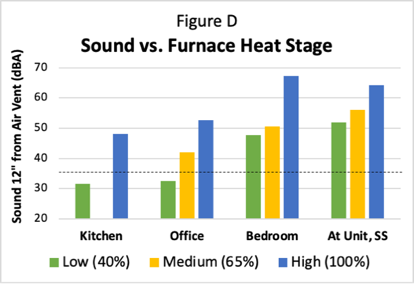

For three levels of heat output (40%, 65%, 100%), I measured the sound level at the

For three levels of heat output (40%, 65%, 100%), I measured the sound level at the

unit and at the supply air vents in three different rooms. (5)

The results confirm a significant sound benefit when operating at less than

full capacity, as seen in Figure C. In all locations, the sound level on low

stage was over 10 dBA less than high stage. In acoustic

engineering terms, this is more than a 50% reduction in loudness!

(6)

For the room air vent measurements, the sound reduction from

high stage to low even greater – on the order of 20 dBA in most rooms, or a 4X

reduction in loudness!

Even the reduction from high to medium stage, representative

of a two-stage design, is significant: 7 dBA at the unit and ~10-dBA in

some rooms. If one cannot afford a modulating design, then two-stage is a

great alternative.

In summary, if quiet furnace operation is important to you,

consider purchasing either a two-stage or modulating sealed combustion furnace

– and maybe you won’t have to turn up the volume while watching your favorite TV

show!

Dan Dempsey is the retired Senior Technical Fellow of

Residential Systems, and former Director of Heating Products Development, for

Carrier Corporation, formerly part of United Technologies Corporation.

Dan has over 40 years’ experience in HVAC product and system design and holds over

40 US patents and patent applications in HVAC product & system design.

He was the recipient of the GAMA and Carrier Engineering Award and now consults

to American Heating & Air Conditioning Co, founded by his grandfather in 1936

and led by his brother Mike Dempsey.

Notes:

(1) https://www.carrier.com/residential/en/us/products/furnaces/59tp6/

(2) Another description for sealed combustion is “direct vent” and is often

used by manufacturers and code officials.

(3) Based on sound measurements on the sealed combustion furnace in my home using

NIOSH SLM software. Unit sound was measured at 45 degrees from the front

left, ~12” from the corner, waist-high. Sound trace averaged over 30

seconds after burner ignition and before circulating air blower energized.

(4) Some furnaces allow the combustion air pipe to terminate inside a vented

attic. This provides the sound and energy benefits of sealed combustion,

while greatly reducing the risk of frost and ice buildup. Consult with

your HVAC contractor whether this would be a feasible option for your house.

(5) Based on sound measurements on the sealed combustion furnace in my home using

NIOSH SLM software. Unit sound was measured at 45 degrees from the front

left, ~12” from the corner, waist-high. Circulating air and combustion

blowers were operating with gas burners lit. Measurements were also taken

at supply air vents in multiple rooms, with the microphone located 12” from the

center of the vent outlet.

(6) https://www.engineeringtoolbox.com/sound-pressure-d_939.html